Methods for Reducing Total Suspended Solids in Wastewater

Total suspended solids (TSS) are a significant concern in wastewater treatment. Too many of these solids can cause many problems, including reduced efficiency in the treatment process, decreased water clarity, oxygen depletion, harboring of harmful bacteria, and clogging of pipes and filter. Having too many solids will also negatively affect your budget in many ways:

- You will need more chemicals in your treatment.

- Bacteria and biofilm issues love TSS.

- Discharge permits often have TSS and Chemical Oxygen Demand (COD) restrictions with high surcharges.

- If your TSS is organic, the TSS directly affects your COD. Therefore, by removing TSS, you will reduce your COD levels.

- TSS destroys pumps.

- Can clog or significantly reduce the efficiency of heat exchangers.

What are Total Suspended Solids (TSS)?

Total suspended solids (TSS) are small particle pollutants that can be found in wastewater. TSS can come from a variety of sources, including:

- Leaves, grass, and sewage

- Industrial and manufacturing effluents

- Manure and municipal wastewater treatment plants

- Runoff from agriculture and urban areas

- Stormwater runoff

Strategies For TSS Wastewater Treatment

There are several methods for TSS wastewater treatments. The trick is to determine which one, or combination, is best for your application.

The first test we typically recommended is getting a Particle Distribution Count test. This test shows you the amounts of solids per size. For example, how many particles are 1-micron, 5-micron, 7-micron, 10-mincron, etc. This information allows you to quickly determine which technologies to use, their loading rate, and other information to help make an educated starting point decision.

Physical Separation

This involves screens, sediment filters, depth filtration, and strainers. The balance needed on effectiveness verse budget is determine operating costs. For example, cartridge filters are typically the lowest upfront cost, however, if you then go through a lot of filters your operating costs will be high. There’s typically a relationship between upfront solution costs and operating costs.

On high TSS applications with small particles, depth filtration is often a good solution. Be cautious when using piston type control valves because the piston will rub the solids against the o-rings and spacers, causing high maintenance costs. Rotary valves do not have this problem.

On high TSS applications with large particles, take a look at automatic strainers. This technology has come a long way in recent years.

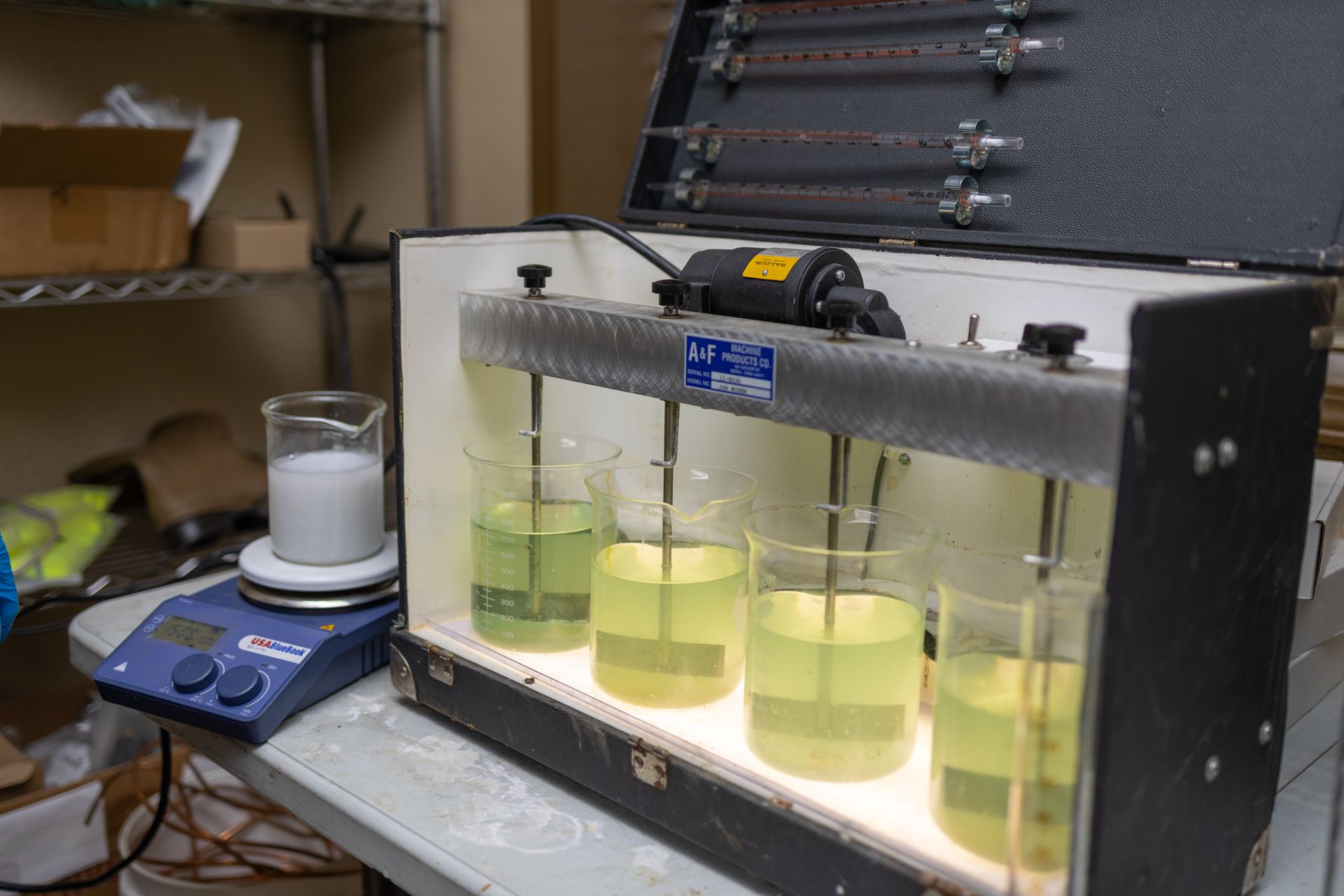

Chemical Precipitation

This involves using specific chemicals, also called polymers, to cause solids to clump together to form large solids that can be more easily removed. This is also called coagulation and flocculation. When this is typically applied, dewatering bags, filter presses, or auto strainers can be used to remove the solids.

Chemical Precipitation Design Hint: Using the newer auto-strainer products can easily remove the need for large settling basins or clarifiers, and are significantly less expensive.

Biological Treatment

This involves using bacteria and other organisms to break down the solids. Anaerobic and/or aerobic strategies are used. Anaerobic bacteria want no to little Oxygen and aerobic needs Oxygen.

Aerobic Strategy Hint: Adding air with a Venturi or injector is often much more cost effective than blowers.

Anaerobic Strategy Hint: This application almost always produces a biogas. New technologies for taking the biogas through an electric generator are becoming very cost effective. Transform your waste stream into an income stream.

Oxidizing

Oxidizing is the process of using Oxygen to destroy organic TSS, or using Oxygen to cause a chemical reaction that increases the size of the TSS, which makes it easier to remove. Many expensive TSS removal plants have been replaced with an inexpensive Oxidizing agent. Aeration, Ozone, ultraviolet (UV), and Hydroxyl Radical generators are common solutions.

Design Hint: Hydroxyl Radical Generators are very cost effective.

Benefits of TSS Wastewater Treatment

Some of the benefits of reducing total suspended solids (TSS) in wastewater include:

- Improved water quality

- Reduced risk of contamination

- Less clogging and fouling of pipes and other infrastructure

- Fewer hazardous sludge deposits

- Improved treatment plant performance

How to Determine Whether Your Water System Meets TSS Reduction Requirements

Most water systems are required to meet specific total suspended solids (TSS) reduction levels set by state and federal regulations. You can check with your local water utility or state environmental agency to find out your area's specific TSS reduction requirements.

You can also ask for a copy of your water system's discharge permit, which will list the TSS reduction levels that your system is required to meet. To find out if your water system meets these regulatory requirements, you can request a copy of your water quality report from your local water utility. This report will show the total suspended solids (TSS) concentrations in your

treated wastewater.

Ways to Prevent TSS from Entering Your Wastewater System

You can also take steps to prevent total suspended solids from entering your wastewater in the first place. Some best practices include:

- Regularly cleaning your facility

- Reducing the number of pollutants entering the sewer system

- Using proper oil and grease disposal methods

- Improving sewage treatment and stormwater management

- Installing filters or other treatment devices to remove TSS from water

Seek Professional Assistance with TSS Wastewater Treatment

No matter what method you use for TSS wastewater treatment, it's essential to monitor your water quality and make adjustments as needed regularly. Keeping total suspended solids under control can help ensure that your water is safe and clean.

If you are concerned about total suspended solids in your wastewater, contact a professional for help.

MAC Water Technologies offers various services to help industries reduce total suspended solids in their wastewater. We can help you

choose the best treatment method for your needs and provide ongoing support to ensure your system operates effectively.

Contact us today to learn more about our custom water and wastewater solutions.